From my position as a factory owner in China, I’ve had a front-row seat to the incredible evolution of manufacturing, especially for products we export to the USA, Europe, and Australia. The rise of the smart home has been revolutionary, and at the heart of this transformation is the smart lock. This device is more than a gadget; it's the guardian of our homes and businesses, a fusion of robust physical security and sophisticated technology. For a procurement officer like my client Mark, the challenge isn't just to source a smart lock, but to find a lock manufacturer who is deeply committed to quality control.

A faulty door lock isn't just an inconvenience—it's a critical failure of trust. That's why I'm writing this guide. I want to pull back the curtain on the world of smart lock manufacturing and show you what true quality control looks like from the factory floor. This is an insider's look at the processes, standards, and mindset required to build a lock solution you can depend on. Understanding these details is the key to forging a successful partnership and ensuring the final product on your shelf meets the highest standards of safety and reliability.

Why is Rigorous Quality Control Non-Negotiable in Smart Lock Manufacturing?

In the lock industry, reputation is everything. For traditional locks, this was built on physical strength and durability. Today, in the smart lock industry, that foundation must be expanded to include flawless electronic performance, cybersecurity, and absolute reliability. Quality control is no longer a final check; it's a philosophy embedded in every step of the lock manufacturing process. A single defect, whether in the casting of the deadbolt or the firmware of the PCB, can compromise the security of a home.

The stakes are incredibly high. For homeowners, a malfunctioning smart lock could mean being locked out or, far worse, a security breach. For businesses like yours, selling a faulty product leads to costly returns, damaged brand reputation, and potential legal liabilities. This is why a strict quality program is the most critical asset a lock manufacturer can possess. It’s the promise we make to our partners and their customers that our product will work perfectly, every time. It’s about building trust, bolt by bolt, and circuit by circuit.

What Does a Comprehensive Quality Control Process Look Like in Lock Manufacturing?

Many people think of quality control as a single inspection at the end of the production line. This is a dangerous misconception. A truly comprehensive quality control process is a multi-stage strategy designed to detect and correct issues long before they reach the final product. At our facilities, we structure our quality assurance around four key pillars:

- Incoming Quality Control (IQC): This is the first checkpoint. Before any

raw materialenters our production line, it undergoes rigorous testing to ensure it meets our specifications. - In-Process Quality Control (IPQC): Our

QCteams conduct continuousinspectionsat critical stages of the manufacturing process—from die-casting andmoldingto PCB assembly and surface finishing. - Final Quality Control (FQC): Once a

smart lockis fully assembled, it goes through a battery of tests. This includes functional testing (lock/unlock cycles, app connectivity), aesthetic checks, and packaginginspection. - Outgoing Quality Control (OQC): Just before shipment, we conduct a final random

inspectionof the packaged goods to ensure theproduct meetsthe client's order specifications and is ready forexport.

This layered approach ensures that quality standards are maintained throughout production, not just assessed at the end. It's a proactive system designed to build quality in, rather than trying to inspect defects out.

How Critical is Raw Material Inspection for a Durable Smart Lock?

The most advanced smart lock in the world is useless if it's made from substandard materials. The final product can only ever be as good as its weakest component. This is why the IQC stage is arguably one of the most important. A smart lock must withstand physical force, resist corrosion from the elements, and its electronic components must endure for years.

When we receive a shipment of raw material, whether it's a batch of zinc alloy for the lock body or a reel of microchips for the circuit board, our inspection process is meticulous. We conduct tests for:

- Material Composition: Using spectrometry to verify the alloy's composition.

- Hardness and Tensile Strength: Ensuring the lock can resist physical attacks.

- Corrosion Resistance: Salt spray testing to simulate harsh weather conditions.

- Electronic Component Viability: Verifying the specifications of all chips, sensors, and motors.

Skipping this step is a common corner-cutting tactic by lower-tier suppliers, but it inevitably leads to product failures down the line. A strong commitment to raw material quality is a clear indicator of a trustworthy manufacturer.

What are the Key Inspection Stages Throughout the Smart Lock Supply Chain?

A modern supply chain is complex. In smart lock production, various components are often sourced from different specialized suppliers before coming together for final assembly. Effective quality control requires oversight at every link in this chain. We work closely with our component suppliers and implement strict inspection points to catch any deviation early.

For instance, after the lock bodies are die-cast, they undergo an inspection for structural integrity and dimensional accuracy before they are sent for polishing and plating. The Printed Circuit Boards (PCBs), the "brains" of the smart lock, are tested separately to ensure all soldering is perfect and the firmware loads correctly. Fingerprint sensors are calibrated and tested for accuracy. By having these checkpoints integrated into the supply chain, we ensure that each component part is perfect before it's integrated into the whole. This prevents the costly and wasteful scenario of discovering a faulty internal component only after the smart door lock has been fully assembled.

How Do Top Door Lock Manufacturers Ensure Quality During Assembly? (A Case Study)

Let's walk through a brief case study of how we ensure quality during the assembly of a high-end intelligent door lock, such as a model with 3D facial recognition. This isn't just about screwing parts together; it's a delicate process where human skill and automated testing intersect.

- Sub-Assembly Testing: Before the main assembly, the core electronic module (PCB, motor, and locking mechanism) is put together. This sub-assembly is placed in a jig that simulates thousands of lock/unlock cycles to test the motor's

durabilityand the mechanism's smoothness. We also test battery consumption during this phase to ensure it meets our low-power standards. - Sensor Integration and Calibration: Next, advanced components like the 3D facial scanner or fingerprint sensor are integrated. Each sensor is individually calibrated using specialized

testing equipmentto meet our strict accuracy and speedtesting standards. - Full Functional Testing: Once fully assembled, every single

lockis connected to ourmanagement software. We test every function: facial recognition, keypad entry, app connectivity via Wi-Fi and Bluetooth, emergency key override, and tamper alarms. We don't just sample a few—we test them all.

This methodical, multi-step process for every unit is how reputable door lock manufacturers build a product that is reliable from the moment it comes out of the box.

For any business involved in procurement for international markets, certification is a non-negotiable topic. This is a major pain point for many buyers, as fraudulent certificates are unfortunately common. A professional export partner will not only have the necessary certifications but will also be transparent in providing the documentation to prove it. These aren't just pieces of paper; they are proof that a product meets critical standards for safety, quality, and regulatory compliance.

Here are the key certifications to demand for electronic products like smart locks:

CE: A mandatory marking for products sold within the European Economic Area. It signifiescompliancewith health, safety, and environmental protection standards.FCC: Required for all electronic devices sold in the United States that have radio frequency emissions (like Wi-Fi or Bluetooth). It ensures the device won't interfere with other wireless services.UL/ ETL: A certification from Underwriters Laboratories (or a similar body like Intertek) that indicates the product meets established safety standards, particularly for electrical shock and fire hazards.RoHS: (Restriction of Hazardous Substances) This directive restricts the use of specific hazardous materials found in electrical andelectronic products.Complianceis mandatory for products sold in the EU.ISO9001: Thiscertificationrelates to the manufacturer'squality controlsystems themselves, showing they have a framework for consistentproduct quality.

Always ask for the full testing reports and verify the certification number with the issuing body. A trustworthy partner will encourage this diligence.

How Can a Procurement Partner Evaluate a Potential Lock Manufacturer's QC?

As a buyer, you need effective ways to evaluate a potential supplier's commitment to quality. While an on-site factory visit is the gold standard, it's not always feasible. However, there are several things you can do remotely to gauge their capabilities.

First, start a detailed conversation about their quality control process. Ask specific questions based on the four pillars (IQC, IPQC, FQC, OQC) mentioned earlier. A knowledgeable supplier will be able to explain their process in detail. Ask for documentation, such as their internal quality manual, sample inspection reports, and a list of their testing equipment. Reputable lock companies are proud of their investment in quality and will be happy to share this information. You can also hire a third-party inspection service to conduct product inspections on your behalf before shipment. Their unbiased report can provide invaluable peace of mind and verify the manufacturer's claims. For instance, testing the advanced features of a custom 3D face smart lock requires specialized equipment that a manufacturer should be able to demonstrate they possess.

What are the Selection Criteria for a Reliable Smart Lock Manufacturing Partner?

Choosing the right manufacturing partner is one of the most critical business decisions you'll make. It goes beyond simple affordability. You are choosing a partner to help you build your brand's reputation. Based on my experience, here are the key selection criteria to consider:

| Criteria | Why It Matters |

|---|---|

| Transparent QC Process | Shows a commitment to quality at every stage, not just a final inspection. |

| Comprehensive Certifications | Ensures the product is safe, legal for export, and compliant with your target market’s regulations. |

| Strong R&D Capabilities | Indicates the partner is innovative, can solve problems, and designs quality into the product from the start. |

| Clear Communication | Essential for a smooth procurement process, preventing misunderstandings and delays. |

| Supply Chain Management | A well-managed supply chain ensures consistent quality and on-time delivery. |

| OEM/ODM Experience | Shows they have the flexibility and expertise to meet your specific requirements. |

A company that ticks these boxes is not just a supplier; they are a strategic partner invested in your long-term success.

The Role of R&D in Ensuring Long-Term Product Quality and Compliance

Quality control doesn't begin on the factory floor; it begins at the design stage. A strong Research & Development (R&D) department is fundamental to creating a reliable and secure smart lock. The R&D team is responsible for much more than just creating a sleek design.

Their role in product development is to ensure compliance with international standards from the ground up. This includes selecting the right materials for durability, designing robust electronic architecture, and—critically for an IoT device—implementing strong cybersecurity protocols to protect user data. They conduct extensive simulation and prototype testing to identify potential weaknesses before mass production even begins. A lock manufacturer with a weak or non-existent R&D team is always playing catch-up, fixing problems as they arise. A manufacturer with a world-class R&D team prevents those problems from ever happening in the first place.

How to Optimize Your Supply Chain for Quality and Timely Delivery?

A great product is meaningless if it doesn't reach your market on time. Delays in the supply chain can lead to missed sales seasons and frustrated customers—a pain point I know many international buyers face. A superior manufacturing partner works with you to optimize the entire supply chain, not just the production part.

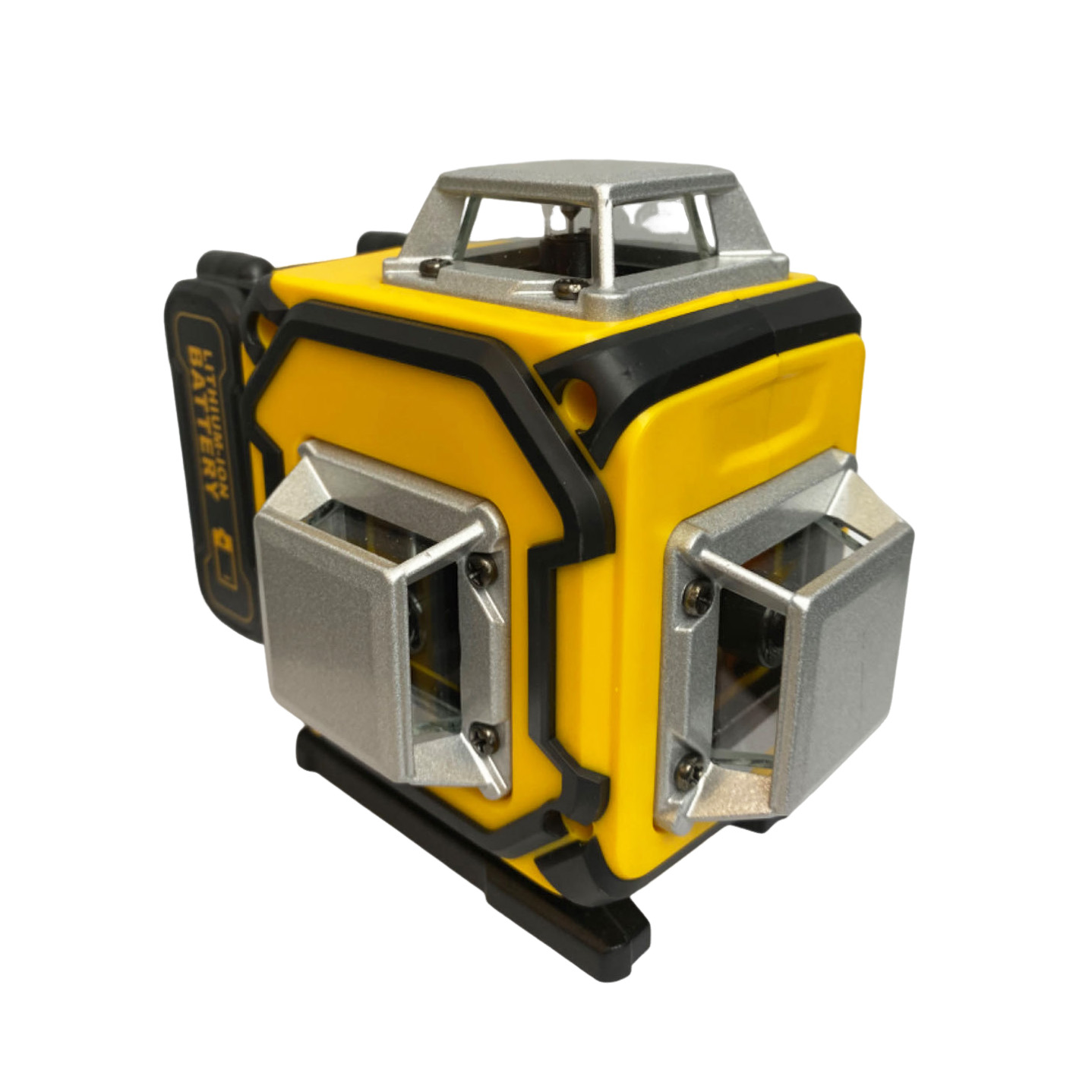

This starts with transparent production planning and realistic lead times. A well-managed factory can forecast production and give you reliable shipping dates. We also help our partners optimize logistics by consolidating shipments and choosing cost-effective yet reliable freight options. Furthermore, having a vertically integrated supply chain, where we control more of the manufacturing processes in-house (from molding to assembly), gives us greater control over both quality and timelines. This reduces reliance on outside suppliers and minimizes the risk of unexpected delays. Choosing a partner who is also an expert in logistics and supply chain management is a key factor for success in the global marketplace. While we specialize in access control solutions, the principles of quality manufacturing apply across all our product lines, including our extensive range of OEM lithium power tools.

Final Thoughts: Choosing Your Partner

The journey from a block of metal and a handful of microchips to a secure, user-friendly smart lock is a complex one, paved with hundreds of quality control checkpoints. As you source these critical security solutions, remember to look beyond the price tag.

- Demand a multi-stage

quality controlprocess. Quality must be built-in, not inspected-out at the end. - Verify all

raw materialstandards. The foundation of a gooddoor lockis the quality of its materials. - Insist on authentic, verifiable

certification. This is your guarantee of safety,compliance, and market access. - Look for a true

manufacturing partner. Choose asupplierwith strong communication, robustR&D, and a deep understanding of your needs.

By using this framework, you can confidently evaluate and select a partner who will help you deliver a product that provides genuine security and peace of mind to homes and businesses everywhere.

Post time: 10 月-20-2025