Hello, I'm Allen, and I've spent years in the heart of China's power tool manufacturing industry. At SavageTools, we operate 7 production lines, specializing in cordless lithium power tools and equipment, exporting primarily to the USA, North America, Europe, and Australia. We understand that for many, from DIY enthusiasts to professional contractors, the choice between an impact driver vs drill can be confusing. Both are essential, but they excel in different areas. This article aims to demystify these two tools, explain the difference between an impact driver and a standard drill, and help you understand when you truly need an impact driver. We'll delve into their mechanisms, best uses, and even touch upon how professionals like Mark Thompson, a 54-year-old company owner and procurement officer from the USA, make their purchasing decisions. Mark is quality-sensitive, seeks competitive pricing, and his key concerns include quality inspection and certifications (like CE, UL), which we prioritize. So, if you want to make an informed choice and ensure you have the best tool for your job, this guide is for you.

What Exactly is a Standard Drill and How Does It Work?

A standard drill, often called a drill driver, is probably the power tool most people are familiar with. Its primary function is to bore holes into various materials like wood, metal, plastic, and sometimes masonry (with the right drill bit). A drill works by using an electric motor (either cord-powered or cordless battery-powered) to provide continuous rotational force to the drill bit. This steady rotation allows the sharp edges of the drill bit to cut into the material, creating a clean hole. Most modern drills also feature a clutch mechanism. This allows you to adjust the amount of torque (twisting power) the drill applies, which is particularly useful when you use a drill to drive screws, as it helps prevent over-tightening or stripping the screw head.

The versatility of a drill is one of its biggest strengths. You can find a wide array of drill bit types, including twist bits for general drilling, brad-point bits for clean holes in wood, spade bits for larger holes, and even hole saws for very large diameter holes. Many cordless drills also come with variable speed settings, allowing you to match the drill's speed to the material and the drill bit being used. For instance, drilling metal typically requires slower speeds than drilling wood. The drill is a foundational tool, and its ability to perform precise drilling tasks makes it indispensable for many projects. When you need to drill holes with accuracy, a drill is usually your go-to power tool.

From my experience as a manufacturer, the engineering of a good drill focuses on balance, precision, and consistent power delivery. When we design a new drill model, like our popular Cordless Lithium Brushless Drill SG-DN45-BL21, we pay close attention to the motor efficiency, the quality of the drill chuck (the part that holds the drill bit), and the ergonomics for comfortable use. A reliable drill should feel like an extension of your hand, allowing for controlled and accurate work whether you're making pilot holes or performing more demanding tasks. This type of drill is a staple for both DIYers and professionals.

Understanding the Impact Driver: What Makes It Special?

Now, let's talk about impact drivers. While they might look somewhat similar to a drill, their internal mechanism and primary purpose are quite different. An impact driver is specifically designed for driving screws and other fasteners with high efficiency and torque. What makes an impact driver special is its internal impact mechanism. As the driver bit encounters resistance (like when a screw gets tight), this mechanism engages, delivering a series of rapid, strong rotational bursts, or "impacts," in addition to the continuous rotational force. Think of it as a tiny hammer hitting the back of the anvil connected to the output shaft, many times per second.

This impacting action is what gives impact drivers their significantly higher torque output compared to a standard drill. This means they can drive screws – especially long or large-diameter ones – into tough materials with much less effort from the user and a lower chance of stripping the screw head. Another key feature of impact drivers is their chuck. Instead of the adjustable three-jaw drill chuck found on a typical drill, impact drivers use a quick-release 1/4-inch hex collet. This collet is designed to hold hex shank driver bits and some specialized hex shank drill bits.

The use of an impact driver truly shines when you're dealing with tasks that require a lot of power for driving fasteners. For example, building a deck, framing walls, or any job involving driving large screws into wood benefits immensely from an impact driver. The concussive blows help to seat the fastener firmly without requiring a lot of downward pressure from the user, which can reduce fatigue. We often hear from our B2B customers, like Mark Thompson, that their clients (construction companies and professional contractors) increasingly demand powerful cordless impact drivers because they significantly speed up repetitive fastening tasks. Impact drivers are made for power and speed in driving, not primarily for precision drilling like a drill.

Impact Driver vs Drill: What's the Main Difference in Mechanism and Power?

So, what’s the difference between an impact driver and a regular drill? The main difference lies in how they deliver force and their intended primary applications. A drill applies smooth, consistent rotational force, making it ideal for drilling precise holes. It features an adjustable clutch to control torque, which is useful for delicate tasks and driving smaller screws. The drill chuck on a standard drill is versatile, accepting a wide range of round and hex shank drill bits for various drilling applications.

On the other hand, an impact driver combines rotational force with a powerful, rapid hammering action (impacts) that occurs in the direction of rotation. This impact mechanism generates significantly more torque than a drill, making impact drivers exceptionally good at driving long screws, lag bolts, and other large fasteners into dense materials with minimal effort from the user and less chance of cam-out (when the driver bit slips out of the screw head). Impact drivers provide this high torque in quick bursts. They typically have a 1/4-inch hex collet designed for driver bits with a hex shank.

To put it simply:

- Drill: Best for drilling holes with precision. Can drive screws, but with less torque and more user effort for larger fasteners. Has an adjustable clutch and a versatile drill chuck.

- Impact Driver: Best for driving screws and fasteners, especially large ones or into tough materials. Delivers high torque through impacts. Uses a 1/4-inch hex collet. Less ideal for drilling precise holes.

The power and torque difference is substantial. While a good cordless drill might offer 500-800 inch-pounds of torque, an impact driver can easily deliver 1500-2000 inch-pounds or more. This is the key differences that dictates what each power tool is best suited for. Understanding this difference between the two helps in selecting the right tool for the job, a crucial factor for professionals who rely on efficiency. A drill is a finesse tool; an impact driver is a power tool.

When is a Drill the Superior Choice for Your Task?

A drill is the superior choice in several situations, primarily when precision and control in hole-making are paramount. If you need to drill clean, accurate holes of various sizes, a drill is your go-to tool. Its smooth, continuous rotational power, combined with the ability to use a vast array of drill bit types (twist bits, spade bits, Forstner bits, hole saws), makes it incredibly versatile for drilling into wood, metal, plastics, and even masonry when using the correct type of drill bit. The adjustable clutch on most drills is another significant advantage, allowing you to set the torque to prevent over-driving screws or damaging delicate materials. This feature is particularly useful when working with smaller screws or softer woods where too much power could strip the screw or the material.

You should use a drill when:

- Drilling precise holes: For dowel joints, pilot holes for intricate woodworking, or any application where hole accuracy is critical.

- Using a variety of drill bit types: If your project requires bits that don't have a 1/4-inch hex shank, like larger twist bits or specialized Forstner bits, a drill with its adjustable drill chuck is necessary.

- Working with delicate materials: The clutch control helps prevent damage.

- Needing smooth, consistent rotation: For tasks like using wire brushes, sanding attachments, or paint mixers that fit into a drill chuck.

- Drilling large diameter holes: While an impact driver might try, a powerful drill with a side handle is often better and safer for controlling large hole saws or auger bits.

Essentially, any task that requires finesse in drilling, a wide range of bit compatibility, or controlled torque for driving smaller screws points towards using a drill. While a drill can also be used to drive screws, its primary strength and design focus is on creating holes. The drill works best when precision is the name of the game. For construction companies and DIY retailers we supply, having a reliable drill in their inventory is non-negotiable due to its broad applicability. Many users will own a drill first, before considering an impact driver.

Why and When Should You Use an Impact Driver?

You should use an impact driver when your primary task involves driving screws, especially long screws, large fasteners like lag bolts, or driving many screws repetitively. The high torque and the percussive action of an impact driver make these tasks significantly faster and easier, with less strain on your wrist and arm. The impacts help to sink the screw deeply and securely, even into dense hardwoods or when dealing with stubborn, partially driven screws. This is where the impact driver delivers its true value.

Consider reaching for an impact driver in these scenarios:

- Driving long or large screws: Think deck building, framing, or assembling large wooden structures. An impact driver will drive screws into wood with remarkable ease.

- Repetitive screw driving: If you have hundreds of screws to drive, an impact driver will save you considerable time and effort compared to a drill.

- Working with dense materials: The extra torque helps power through tough woods without bogging down.

- Loosening stubborn fasteners: The same impacting force that drives screws can also help break free rusted or over-tightened bolts and screws (though for very large or rusted bolts, an impact wrench might be even better).

- Reducing cam-out: The downward force combined with rotational impacts helps keep the driver bit firmly in the screw head, reducing the likelihood of stripping.

Many professional contractors, like those Mark Thompson supplies, swear by their impact drivers for efficiency. If your project involves a lot of fastening, an impact driver is often the best tool. While it's not designed for precision drilling, its ability to drive fasteners quickly and powerfully is unmatched by a regular drill. Impact drivers are generally more compact and lightweight than a drill of comparable power, making them easier to handle in tight spaces. So, if you need a tool primarily for sinking screws with power and speed, you definitely need an impact driver.

Can You Effectively Use an Impact Driver as a Drill?

This is a common question: can you use an impact driver as a drill? The technical answer is yes, but with some important caveats. You can purchase hex shank drill bits specifically designed for use with impact drivers. These bits have a 1/4-inch hex shank that fits into the impact driver's collet. So, you can drill holes with an impact driver. However, it's generally not the ideal tool for drilling, especially if you need precision or are drilling into delicate materials.

The main issue with using an impact driver for drilling is the impacting mechanism. While this is great for driving screws, it can be problematic for drilling. The impacts can make it difficult to start a hole accurately, and the resulting hole may not be as clean or round as one drilled with a standard drill. Furthermore, the high torque and impacts can sometimes be too aggressive for smaller drill bits, potentially leading to breakage, or for delicate materials that might crack. Impact drivers also lack the clutch system found on a drill, meaning you don't have the same level of torque control, which is important for preventing damage when a drill bit binds.

So, while you can technically use an impact driver to drill a hole, especially in softer materials or for rough work where precision isn't critical, a standard drill is almost always the better choice if you need to drill holes regularly or require accuracy. If you're only doing occasional, non-critical drilling and primarily need a tool for driving screws, you might get by with an impact driver and some hex shank drill bits. But for most people, especially those doing any amount of woodworking or metalworking, having a dedicated drill for drilling and an impact driver for driving is the most effective setup. The impact driver works best as a specialist tool for fasteners.

Is a Regular Drill Good Enough to Drive Screws?

Yes, a regular drill is certainly capable of driving screws, and for many years before impact drivers became mainstream, drills were the primary power tool for this task. Most cordless drills come with variable speed and an adjustable clutch, which are beneficial when you use a drill to drive screws. The clutch allows you to set the maximum torque, helping to prevent over-tightening a screw or stripping the screw head, especially with smaller screws or softer materials. The variable speed trigger gives you control over how fast the screw is driven.

However, while a drill can also drive screws, it has limitations compared to an impact driver, particularly when dealing with larger or longer fasteners, or when driving screws into dense materials. A drill uses continuous rotational force, and if the resistance becomes too high, the drill might stall, or you'll have to exert significant downward pressure to keep the driver bit engaged and prevent cam-out. This can be tiring and less efficient for heavy-duty fastening tasks. Driving many large fasteners with a drill can put a strain on the drill's motor and on your wrist.

So, for light-duty screw driving, occasional use, or when precision and torque control for smaller screws are important, a drill is perfectly adequate. Many DIYers manage fine with just a drill for all their drilling and screw-driving needs. But if you frequently drive screws, especially in demanding applications, you'll quickly appreciate the power, speed, and reduced user effort offered by an impact driver. The drill is also a more versatile tool overall because of its primary drilling function, but for dedicated, high-volume screw driving, the impact driver has the edge. Using screws with a drill is common, but the experience with an impact driver for tough jobs is notably different.

What About a Hammer Drill? How Does It Fit into the Drill Family?

Now, to add another layer to the drill discussion, let's talk about the hammer drill. A hammer drill is a specialized type of drill that adds a pulsating, hammer-like action along the axis of the drill bit in addition to the rotational motion. This is different from an impact driver, whose impacts are rotational. The hammer drill's percussive blows are designed to help pulverize hard materials like concrete, brick, and masonry as the drill bit rotates, making it much easier to drill into concrete or similar surfaces. Think of it as a drill with a built-in hammer function that pounds the drill bit forward as it spins.

Most hammer drills have a switch that allows you to turn the hammering function on or off. With the hammer mode off, it operates like a standard drill, capable of drilling holes in wood, metal, and plastic, and also driving screws (though, like a standard drill, it's not as efficient as an impact driver for heavy-duty screw driving). When you need to drill into masonry, you engage the hammer mode and use a masonry drill bit. The hammer action is what sets it apart; a regular drill would struggle significantly or fail to penetrate dense concrete effectively.

So, when comparing a hammer drill to an impact driver:

- Hammer Drill: Designed to drill holes in hard materials like concrete and masonry using forward hammering blows combined with rotation. Can also function as a regular drill.

- Impact Driver: Designed to drive screws and fasteners with high rotational torque using rotational impacts. Not designed for drilling masonry.

If your work involves frequently drilling into concrete or brick, a hammer drill is an essential tool. For general wood or metal drilling and light screw driving, a standard drill is fine. For heavy-duty screw driving, an impact driver excels. Some users opt for a hammer drill as their primary drill because of its added versatility for occasional masonry work, effectively giving them drills with the added capability. However, for pure fastening power, the impact driver remains distinct. As a manufacturer, we offer various types of drills, including hammer drills, to cater to these specific needs. Our clients, like Mark Thompson, often procure a mix of standard drills, hammer drills, and impact drivers to serve the diverse requirements of their customer base, which includes construction companies that definitely need an impact driver and a hammer drill.

Torque, Speed, and Chucks: Key Differences Between Impact Drivers and Drills

Let's dive deeper into three critical technical aspects that distinguish an impact driver and a drill: torque, speed, and chuck type. These key differences are fundamental to understanding why each tool is suited for different tasks.

Torque: This is the twisting force the tool can apply.

- Impact Drivers: These are torque monsters. The internal impact mechanism allows them to generate significantly higher rotational torque – often 3 to 4 times more than a typical drill. This high torque (e.g., 1500-2000 in-lbs or more) is what enables impact drivers to drive large fasteners into tough materials with ease.

- Drills: A drill provides a smoother, more controlled torque output. While powerful cordless drills can offer respectable torque (e.g., 500-800 in-lbs), it's considerably less than an impact driver. Critically, drills feature an adjustable clutch that allows the user to limit the torque, which is essential for preventing over-tightening screws or damaging delicate materials when using the drill to drive screws.

Speed: This refers to the rotational speed (RPM - revolutions per minute).

- Impact Drivers: Generally have higher top speeds and also deliver impacts per minute (IPM). The speed is often controlled by the trigger, but the main power comes from the impacts.

- Drills: Most drills offer variable speed settings (often two gears: high speed for drilling, low speed for higher torque applications like driving screws or using large bits). This allows for more finesse. A drill makes it easier to start a hole slowly and accurately.

Chucks: This is the part of the tool that holds the bit.

- Impact Drivers: Feature a 1/4-inch quick-release hex collet. This is designed specifically for bits with a 1/4-inch hex shank, primarily driver bits, but also some hex shank drill bits. Bit changes are very fast – just push in to lock, pull the collar to release.

- Drills: Use a three-jaw adjustable drill chuck. This type of drill chuck can securely hold a wide variety of round-shank and hex shank drill bits of different sizes (e.g., from 1/16-inch up to 1/2-inch, depending on the drill). This makes the drill far more versatile for using different types of drill bits, including those not available with a hex shank.

Understanding these differences between impact drivers and drills in terms of speed and torque, and how their chucks operate, is crucial. It explains why an impact driver delivers superior performance for driving and a drill excels at precision hole-making. The drill and impact driver are designed with these distinct characteristics in mind.

Impact Driver and a Regular Drill: Making the Right Choice for Your Needs

Deciding whether you need an impact driver, a regular drill, or both, depends largely on the type of work you do. Let's break down some common scenarios to help you choose between an impact driver and a regular drill.

For the DIY Homeowner:

- If your tasks primarily involve occasional light repairs, hanging pictures, assembling flat-pack furniture, and drilling small holes in drywall or softwoods, a good quality cordless drill will likely suffice. Its versatility to both drill holes and drive screws (with clutch control) makes it a great all-rounder.

- However, if you're undertaking larger projects like building a deck, a fence, or doing more extensive renovations that involve driving many long screws into wood, then adding an impact driver to your collection will be a game-changer. The impact driver and a drill often make a great pair.

For the Serious Hobbyist or Woodworker:

- You'll almost certainly benefit from having both. A drill is essential for precision drilling, creating pilot holes, and using various specialized bits like Forstner or brad-point bits. An impact driver will handle all your heavy-duty fastening needs, making assemblies quicker and easier. The difference between a drill and an impact driver in their specialized roles becomes very apparent in woodworking.

For Professional Contractors (Construction, Electrical, Plumbing, HVAC):

- Having both an impact driver and a regular drill (often a hammer drill too) is standard. Efficiency and power are key. Impact drivers are used constantly for driving fasteners, while drills (and hammer drills) handle all hole-making requirements, from small pilot holes to large openings for pipes or wiring. Time is money, and these two tools optimize different tasks. Many professionals carry an impact driver on one hip and a drill on the other. They use impact drivers for most fastening and a drill for drilling.

Key Questions to Ask Yourself:

- What percentage of my work involves driving screws versus drilling holes?

- Am I frequently driving long or large fasteners, or working with dense materials?

- Is precision drilling a common requirement for my projects?

- Do I often work in tight spaces where a more compact tool (like many impact drivers) would be beneficial?

As a manufacturer, we at SavageTools provide a range of both cordless drills and tools that complement them, like impact wrenches (which share impact technology). We understand that our B2B clients, like Mark Thompson, need to offer their customers, from hardware stores to construction companies, the right power tool for every specific application. The impact drill (often referring to a hammer drill or sometimes loosely to an impact driver) term can be confusing, so it's important to learn the difference.

A Peek Inside: How Does an Impact Driver Deliver Such High Torque?

The secret to an impact driver's impressive torque lies in its unique internal impact mechanism. While a drill relies solely on the continuous rotational force from its motor and gearing, an impact driver adds a "kick" to this rotation. Let's visualize how an impact driver works internally. Inside, there's a motor, gearing (similar to a drill), a spring, a hammer, and an anvil. The anvil is connected to the output shaft, which holds the driver bit.

Here's a simplified step-by-step:

- When you start driving a screw, the impact driver begins by applying simple rotational force, much like a drill.

- As the screw meets more resistance (e.g., it's driven deeper or hits dense wood), the motor continues to turn the hammer component.

- The hammer is designed to rotate and then slide slightly forward along a ramp or cam mechanism.

- This forward movement, combined with rotation, causes the hammer to strike the anvil with considerable force. This is the "impact." This isn't a forward impact like a hammer drill; it's a rotational impact, a powerful tangential blow.

- The spring then retracts the hammer, allowing it to spin and strike the anvil again very rapidly – often thousands of times per minute (measured as IPM or Impacts Per Minute).

Each of these tiny, rapid rotational "slaps" or impacts from the hammer hitting the anvil adds a burst of torque to the driver bit. This is why an impact driver can generate so much more twisting power than a drill without requiring significant counter-force from the user's wrist. It’s also why impact drivers make a characteristic loud chattering or hammering sound when the impact mechanism is engaged. This design is incredibly effective for driving fasteners because the impacts help overcome static friction and drive the screw continuously, even under heavy load. The impact driver delivers this force efficiently, making it a preferred tool for driving screws. This is a key piece of information to know about impact drivers.

From the Factory Floor: Choosing Quality Drills and Impact Drivers

As someone who oversees 7 production lines in China, manufacturing cordless lithium power tools for global markets like the USA, Europe, and Australia, I, Allen, can share some insights into what makes a quality drill or impact driver. When B2B clients like Mark Thompson come to us, their primary concerns are quality, durability, performance, and, of course, compliance with international safety standards (CE, UL, etc.). These are not just buzzwords; they are critical for tools that professionals and serious DIYers rely on.

What to Look for in a Quality Drill or Impact Driver:

- Motor Technology: Brushless motors are increasingly the standard for better cordless drills and impact drivers. They offer higher efficiency, more power, longer runtime per battery charge, and extended tool life compared to older brushed motors.

- Battery Platform: For cordless tools, the battery is crucial. Look for reputable lithium-ion battery technology that offers good capacity (Ah rating), consistent power output, and ideally, is part of an interchangeable system if you plan to own multiple tools from the same brand. Our focus at SavageTools is on OEM Lithium Power Tools, ensuring robust battery performance.

- Build Quality and Ergonomics: The tool should feel solid and well-balanced in your hand. High-quality materials for the housing, comfortable grips, and good ergonomic design reduce fatigue and improve control. The quality of the drill chuck on a drill or the collet on an impact driver is also important for bit retention and durability.

- Performance Specs (Torque, Speed, IPM): While higher numbers often look better, consider your actual needs. For a drill, smooth operation and good clutch control are as important as raw power. For an impact driver, high torque and IPM are key performance indicators for driving capability.

- Certifications and Safety: Ensure the tools meet relevant safety standards for your region. This is a non-negotiable for us and for discerning buyers like Mark, who often face issues like certificate fraud from less reputable suppliers.

- Supplier Reliability: For B2B buyers, the supplier's reliability regarding quality inspection, consistent manufacturing, logistics, and clear communication is paramount. Pain points like shipment delays leading to missed sales seasons are a real concern.

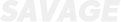

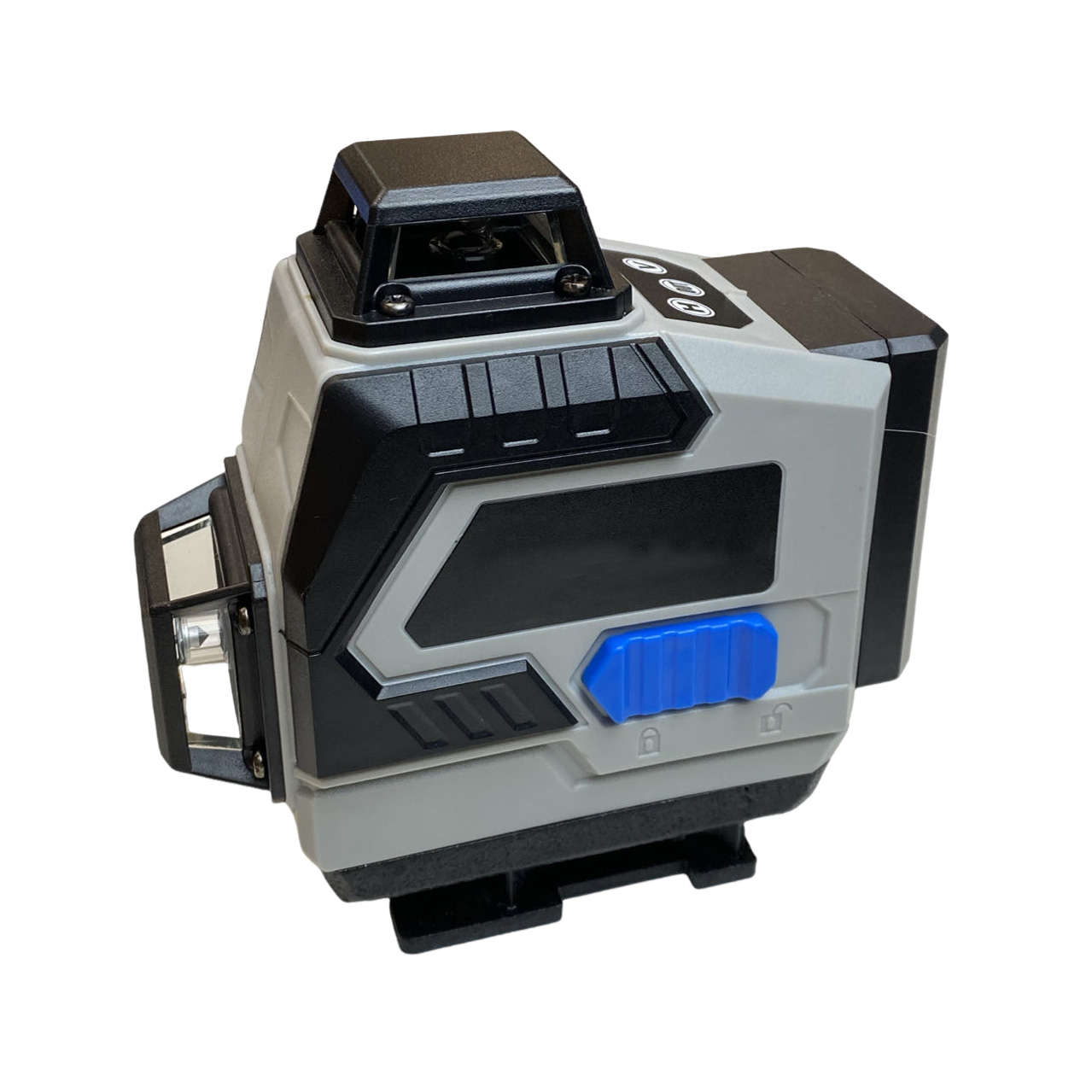

When we manufacture a drill or an impact driver, we focus on these aspects. For example, our Cordless Lithium Angle Grinder SG-AG125-BL21 and other tools like our Laser Level SG-LL12 undergo rigorous testing. Whether it's a simple drill for occasional home use or a heavy-duty impact driver for a construction site, the underlying principles of quality engineering apply. Choosing the right drill and an impact driver combo, or deciding if you only need an impact driver or just a versatile drill, starts with understanding your tasks and then selecting a tool that's built to perform reliably.

Key Takeaways: Impact Driver vs Drill

To wrap up our deep dive into the impact driver vs drill debate, here are the most important things to remember:

- Drills are for Drilling: A standard drill is primarily designed for accurately drilling holes in various materials. Its adjustable drill chuck accepts a wide range of drill bit types, and its clutch offers torque control, which is also useful for driving smaller screws. A drill works with smooth, continuous rotational force.

- Impact Drivers are for Driving: An impact driver excels at driving screws and other fasteners, especially long or large ones, into tough materials. It uses a combination of rotational force and rapid rotational impacts to deliver very high torque. Impact drivers use a 1/4-inch hex collet.

- Main Difference: The main difference between an impact driver and a regular drill is the impact mechanism in the driver, which produces much higher torque for fastening, versus the smooth rotational power of a drill optimized for hole creation.

- Hammer Drills for Masonry: A hammer drill is a specialized drill that adds a forward hammering action to assist in drilling into concrete and brick. It's different from the rotational impacts of an impact driver.

- Can You Interchange? You can use an impact driver as a drill (with hex shank drill bits) for rough work, but it's not ideal for precision. You can use a drill to drive screws, but it will struggle with heavy-duty tasks where an impact driver shines.

- Which Do You Need?

- Light DIY: A good cordless drill might be all you need.

- Serious DIY/Woodworking: Both a drill and an impact driver are highly beneficial.

- Professional Use: Both are essential, often alongside a hammer drill. Consider what you need, a dedicated drill, or if you really need an impact driver.

- Quality Matters: Look for brushless motors, good battery platforms, solid build quality, and appropriate performance specs whether choosing a drill, an impact driver, or any power tool.

Understanding these distinctions will help you choose the right tool, work more efficiently, and achieve better results in your projects. As a manufacturer, my goal is to provide tools that empower users like you, and discerning buyers like Mark Thompson, to get the job done right.

Post time: 5 月-14-2025